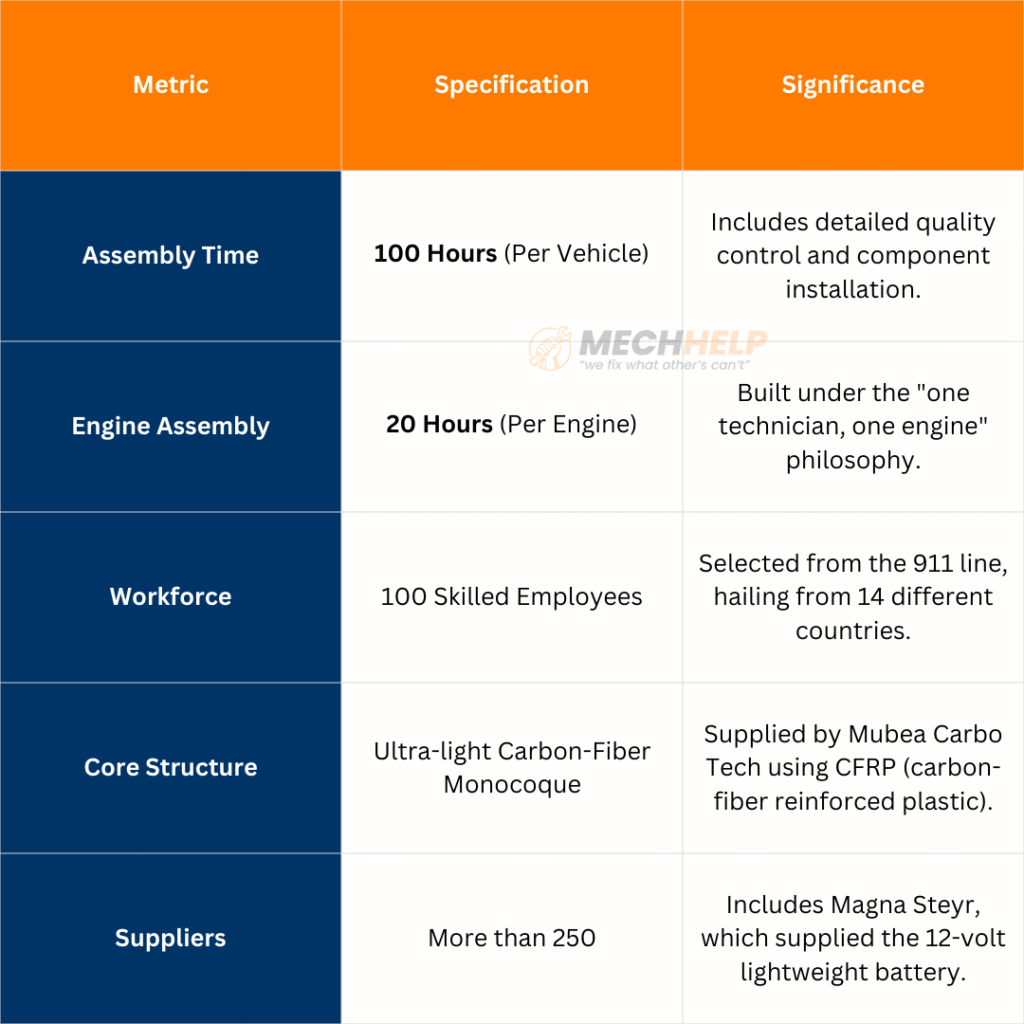

Porsche 918 Spyder assembly Took 100 Hours of Hand-Built Craftsmanship Per Car

The Porsche 918 Spyder may be more than a decade old, but its hybrid performance and legendary status (as part of the Holy Trinity of Hypercars) remain remarkably fresh. The secret lies in its meticulous construction. The Porsche 918 Spyder assembly process required an estimated 100 hours of hands-on work for every single car produced, showcasing the high-tech craftsmanship required for this limited-production model.

This complex process was carried out by a dedicated team of 100 skilled employees in a specially constructed 4,000-square-meter manufactory within Plant 2 at Porsche’s Zuffenhausen facility.

Here is a look inside the highly technical, low-volume assembly of the 918 units produced.

A Hypercar Built by Hand and Data

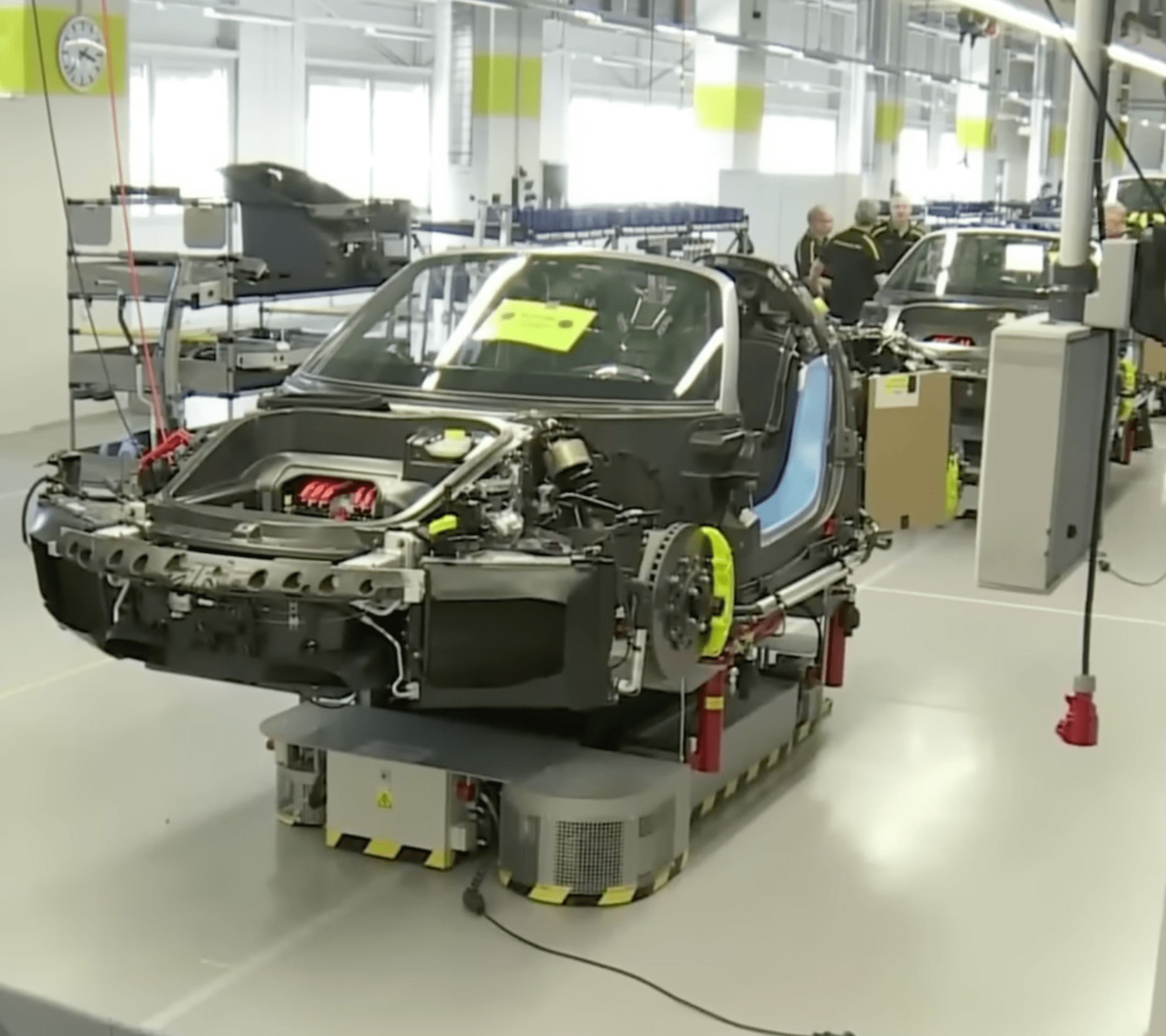

The manufacturing process for the 918 was unlike the regular 911 production line, relying heavily on human skill supported by cutting-edge digital assistance.

The assembly line itself utilized a special one-sided herringbone layout to ensure the shortest paths between sub-assembly sections and the main line.

From Monocoque to Final Bolting

The hypercar’s build began with the two-seater CFRP monocoque, which was engineered specifically to house its hybrid system (a 4.6-liter naturally aspirated V8 and two electric motors for 887 hp).

- Specialized Tools: Workers used modern Bluetooth-controlled cordless torque wrenches to ensure precise, documented compliance with safety-critical torque values for every single bolt.

- Ergonomics: Mechanical scissor lift platforms and battery-powered Automated Guided Vehicles (AGVs) were used to raise, lower, and rotate the chassis as needed, easing the strain on technicians installing interior and underbody components.

- Precision Craftsmanship: Traditional tools still played a role, with vacuum holders positioning the windshield and highly-trained specialists meticulously stitching the leather for the interior components.

The Porsche 918 Spyder assembly concluded in June 2015 as scheduled, and its influence—especially the hybrid technology and manufacturing excellence—continues to shape Porsche models today, providing the foundation for the brand’s Mission X concept, which hints at a future successor.

Also Read – Hyundai Kia 2025 US sales Report Shows Hyundai Ahead By Over 45,000 Units

Pingback: Toyota GR Yaris M Concept MR2 Mule Debuts With New 2.0L Turbo Engine